CHEMICAL FEEDER PUMP SYSTEMS IN MARYLAND

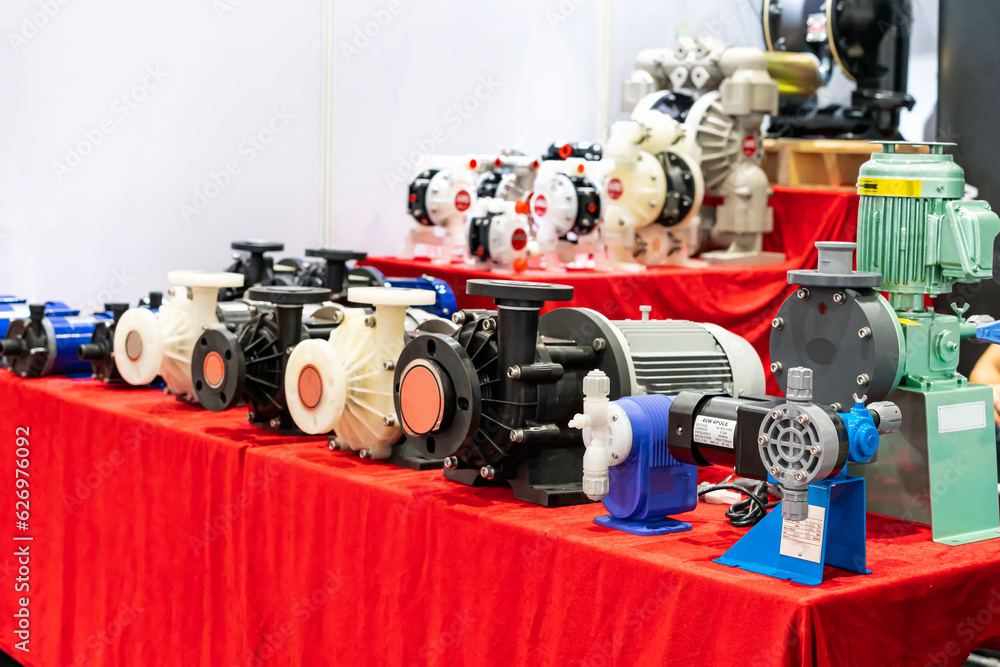

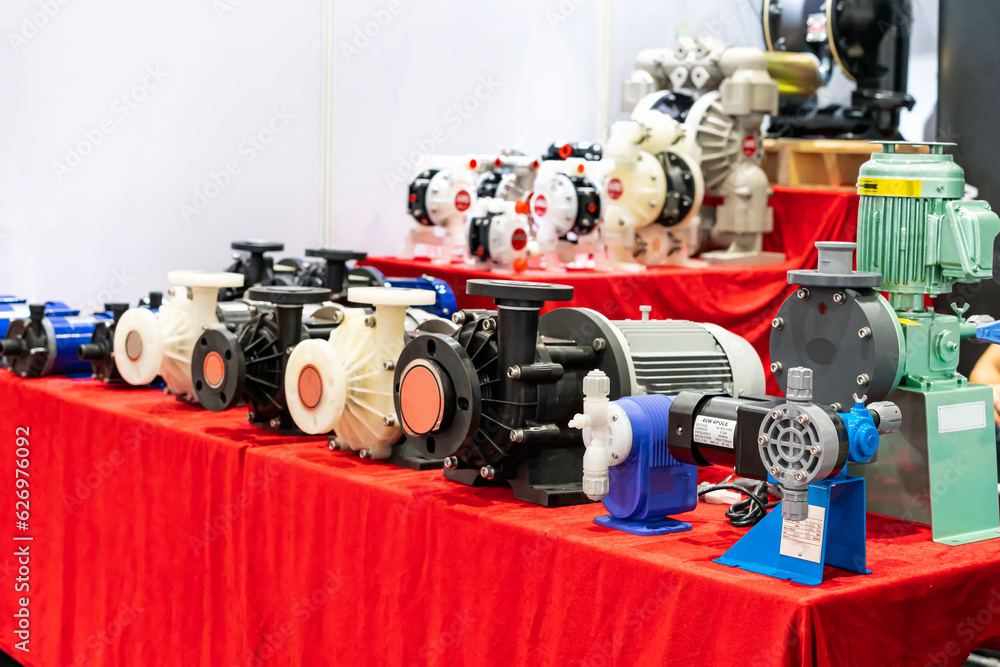

What Are Chemical Feeder Pumps?

Chemical feeder pump systems, also known as chemical dosing or injection systems, deliver precise amounts of treatment chemicals (such as chlorine, acid, antiscalants, or pH adjusters) into a water stream automatically. These systems help treat issues like disinfection, corrosion control, scale prevention, pH balancing, iron & manganese removal, and more.

Chemical dosing with a feeder pump offers advantages over manual mixing or batch dosing:

- Accuracy & consistency: Delivers precise concentrations of chemical regardless of flow fluctuations

- Automation: Eliminates manual dosing, reduces human error

- Efficiency & cost control: Avoids over- or under-dosing, reduces chemical waste

- Scalability & flexibility: Easily adjust dosage rates or upgrade for larger flows

- Safety & containment: Properly engineered systems include containment, controls, and safety features

In water treatment, such systems are used for disinfection, pH control, scale & corrosion inhibition, and more.

What Ensor Plumbing Can Do

At Ensor Plumbing, we design, install, and maintain chemical feeder pump systems tailored to the needs of residential, commercial, or light industrial customers. Our scope includes:

- Water testing & evaluation – to determine the right chemical(s) and dosage

- System design & sizing – selecting pump capacity, tank volume, injection point, controls

- Professional installation – secure mounting, piping, wiring, safety features

- Calibration & commissioning – ensure accurate feed rates and system stability

- Routine maintenance & monitoring – check pump performance, recalibrate, replace components

- Upgrades & retrofits – integrate with your existing water treatment (e.g. RO, softeners, UV)

How It Works (Simplified)

- Chemical preparation

The selected chemical (e.g. chlorine, soda ash, acid) is stored in a tank and, if needed, diluted or mixed to a workable concentration. - Metered injection

The metering pump draws the chemical and injects it into the water line at the precise rate needed, often proportional to water flow. - Mixing & reaction time

After injection, a static mixer, retention tank, or appropriate piping ensures thorough mixing and sufficient contact time for the chemical to act. - Monitoring & control

Sensors or controllers (pH meters, ORP, flow sensors) can adjust dosage in real time, accommodating changes in demand. - Safety & containment

The system includes check valves, back-pressure protection, overflow containment, and fail safes to avoid chemical backflow or leaks.

Common Applications & Chemical Types

Typical uses of chemical feeder systems include:

- Disinfection: dosing chlorine or other biocides

- Dechlorination: injecting sodium bisulfite or similar agents

- pH Adjustment: acids (like HCl) or bases (like sodium hydroxide)

- Scale & corrosion inhibition: antiscalants, phosphates

- Oxidation: peroxide, potassium permanganate

- Metal control / iron & manganese treatment

The same pump infrastructure can often be adapted to serve multiple treatment goals, depending on the chemical and control logic.

Is a Chemical Dosing System Right for You?

You may need a chemical feeder pump system if:

- You have recurring water quality challenges (e.g. bacteria, scale, pH, metals)

- You run a water treatment system (RO, softener, UV) and need chemical pretreatment or post treatment

- Manual chemical dosing is too labor-intensive or error-prone

- You need precise, consistent control over chemical addition

- You want a safer, automated system rather than handling chemicals manually

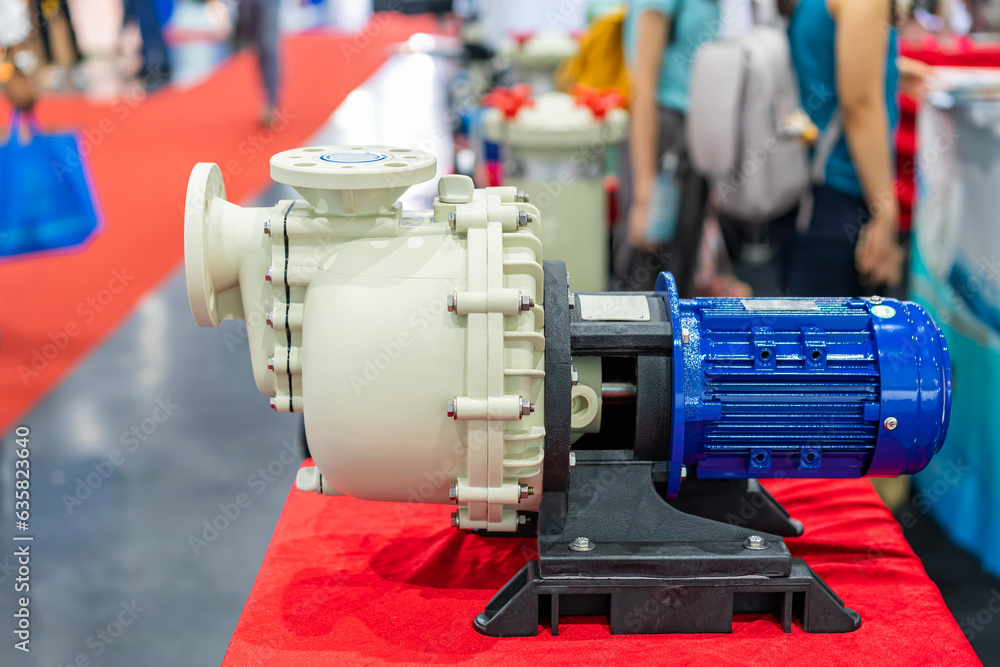

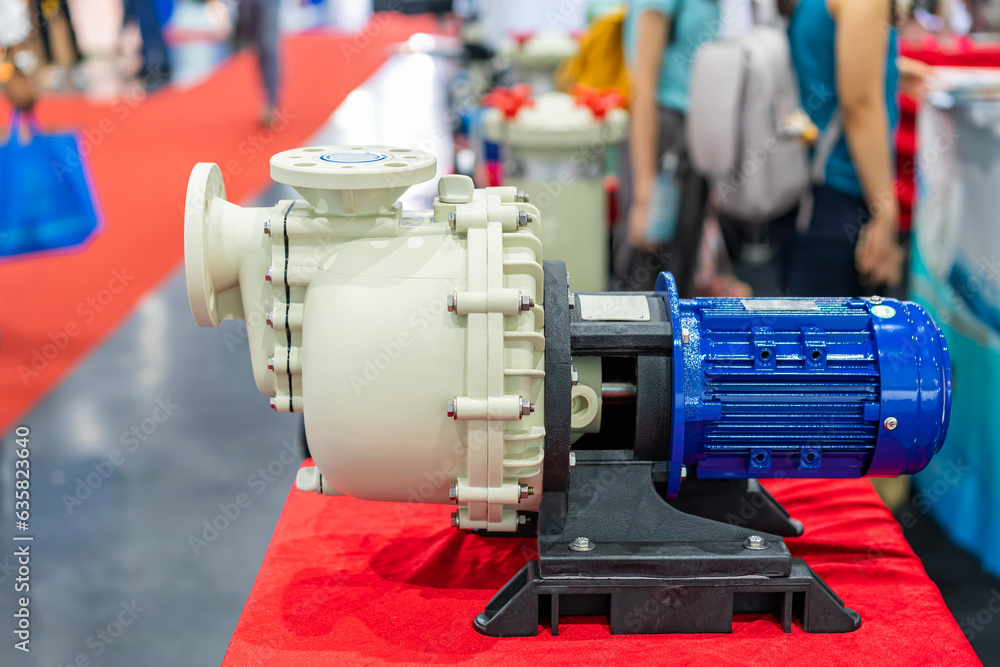

System Installation & Maintenance

- Proper placement & layout: Tanks, pumps, and injection points must be located with safety and accessibility in mind

- Material compatibility: All wetted materials must resist corrosion by the injected chemical

- Flow & dosage calibration: We calibrate and test the pump to ensure it meets design specifications

- Safety features: Secondary containment, leak detection, check valves, alarms, and proper venting

- Routine service: Periodic checks of pump output, diaphragm/seals, tubing, electrical and control systems

- Chemical supply: We can coordinate safe delivery, handling, and refilling of chemical supplies

Request a Custom Quote & Consultation

Ready to harness the power of chemical dosing with a professionally engineered system? Contact Ensor Plumbing today for a complimentary assessment and quote. We’ll test your water, review treatment goals, and design a safe, effective feed pump system that fits your needs.

Let Ensor Plumbing deliver precision, safety, and reliability with chemical feeder pump systems built to perform.

Why You Should Hire Us For Your Plumbing Repairs

When you call us for plumbing repairs, you will receive the best services available in the Baltimore area. Our plumbers possess the skill and experience to keep up to date on all the latest advances in plumbing technology. From small to large troubleshooting jobs, you can count on us to complete the project successfully.

Our goal at Ensor Plumbing is to rid your home of any problems with long-term solutions. Contact our repair experts today to restore or remodel your home to its original safety and comfort. We specialize in a variety of products and equipment and will perform the plumbing repair job you need done in a timely and professional manner.